Paper Honeycomb Board

Home > Products > Paper Honeycomb Board > Paper Honeycomb Board

| Thickness | 6~35 mm |

| Mass Weight | 300~3000 g/㎡ |

| Maximum Width | 1400 mm |

| Production Line | 2 |

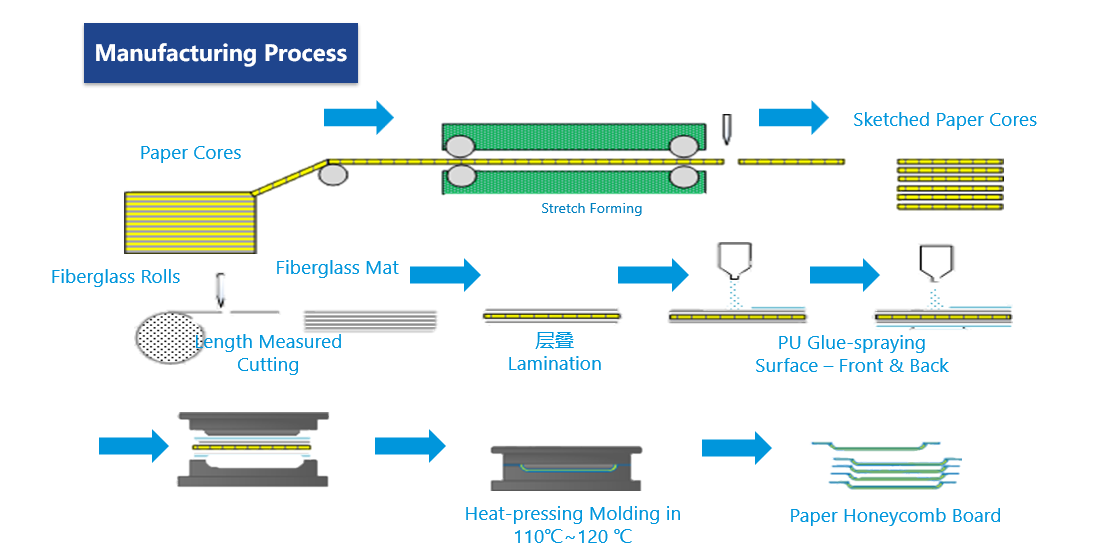

| Manufacturing Skill | Die Cutting, Hot Pressing, Bending, Laser Engraving, Laser Printing, etc. |

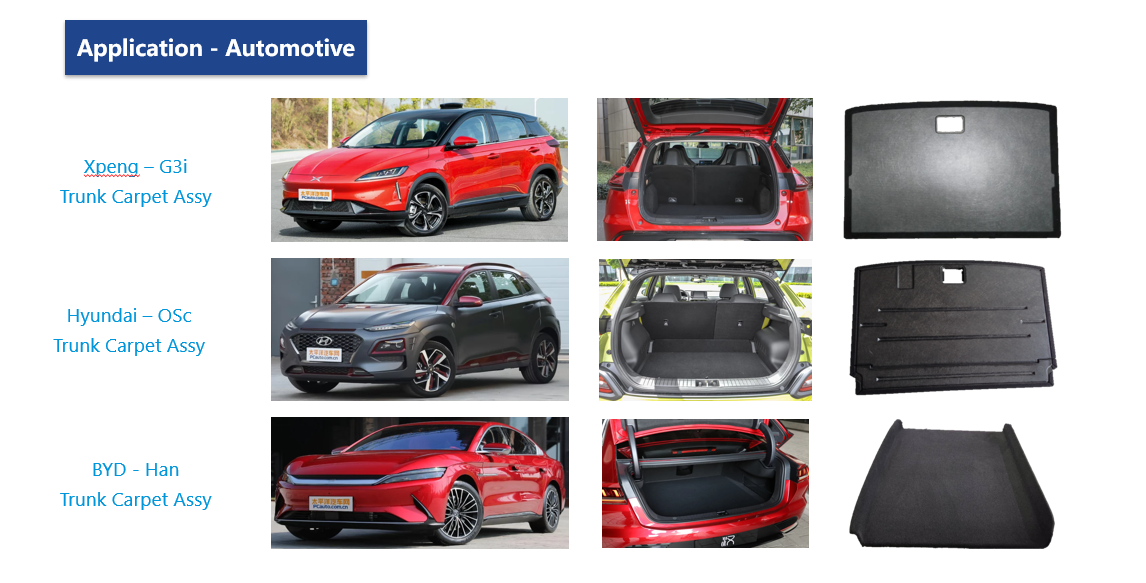

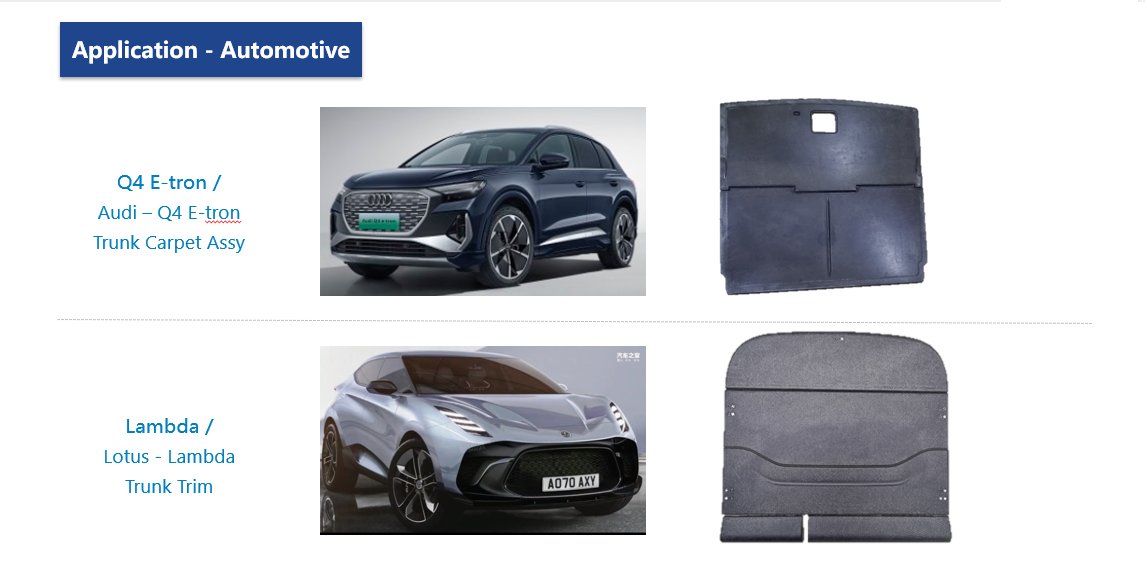

| Main Application | SUV spare tire covers, trunk lid covers, sunroof shades, and clothes hangers. |

| Colors | Black, Dark Grey, Light Grey, etc. |

Products describe

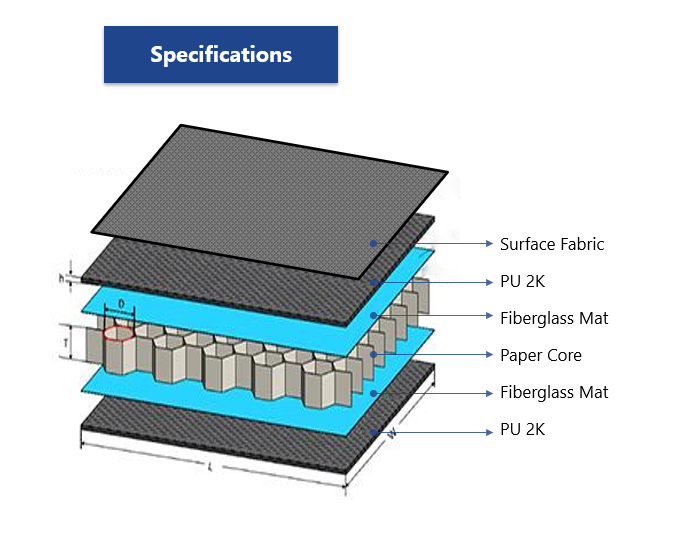

The PHC (Paper Honeycomb) board is a composite material that uses a paper core for support, with fiberglass felts as reinforcement on both sides. The material is coated with polyurethane (PU) using spray technology to form a foamed blank on both surfaces, which is then hot-pressed to shape. This process results in a composite with high load-bearing capacity, strength, and resistance to deformation, while also being lightweight. It is primarily used in automotive interior components such as spare tire covers, sunroofs, and sunshades.

Product Available

| Performance | Tensile Strength | Flexural Strength | Flexural Modulus |

| Testing Standard | ASTM D638 | ASTM D790 | ASTM D790 |

| Unit | MPa | MPa | MPa |

| Typical Value | 15 | 20 | 3000 |

Features

Lightweight, High Strength

Dimensionally Stable, Waterproof

Noise Insulation, Noise Reduction

Good Compressive Strength

Corrosion and Weather Resistance

PP Honeycomb Board Production Line

Application

Inquiries

Please leave true info to make sure your feedback works, we will reply you in 24 hours.